Pipeline Filter – Yg80 Filter & T-Filter

The pipeline filter is mainly composed of a nozzle, a cylinder, a filter basket, a flange, a flange cover and fasteners. It can be installed on the pipeline to remove the larger solid impurities in the fluid, so that the fueling machinery and equipment (including compressors, pumps, etc.) and instruments can work and operate normally, so as to stabilize the process and ensure safe production. The pipeline filter has the advantages of compact structure, large filtering capacity, small pressure loss, wide application range, convenient maintenance, etc.

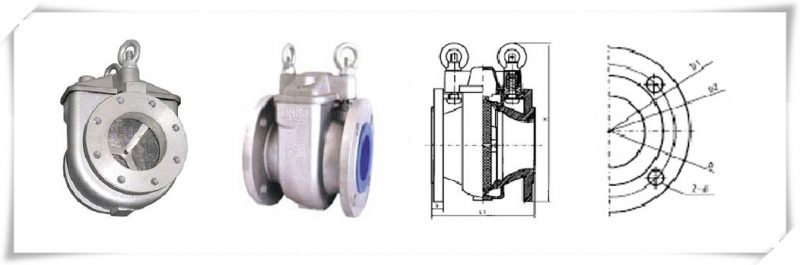

Yg80 Pipeline Filter

Yg-80 Filter belongs to a pipeline filter, which is an indispensable pipeline accessory for the purification of corrosive fluids in industrial production. Yg filter is widely used in steam, air, water, oil and other system pipelines to protect various meters, pumps, valves, steam traps and other equipment. Yg type filter has small pressure loss, large flow area and strong antifouling.

Features:

◈ Material: aluminum alloy

◈ Medium: gasoline, diesel, kerosene

◈ Nominal pressure: 0.2㎫

◈ Ambient temperature: -45℃ – +55℃

Technical Parameter

| Size | L | D | D1 | D2 | Z-d | H | b |

| 2 | 153 | 140 | 110 | 80 | 4-14 | 245 | 14 |

| 3 | 163 | 188 | 150 | 125 | 4-18 | 270 | 15 |

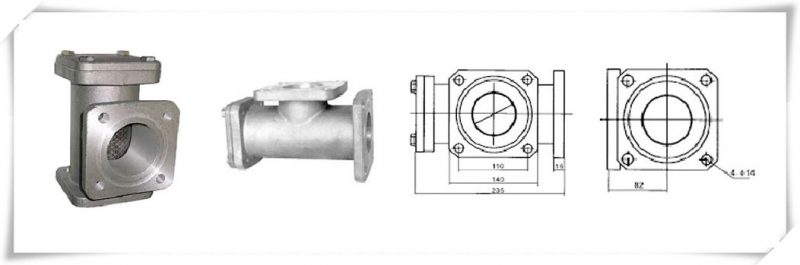

T type Pipeline Filter

T-type filter belongs to the pipeline coarse filter series, and can also be used for the filtration of gas or other medium and large particle materials. It can be installed on the pipeline to remove large solid impurities in the fluid, so that the equipment (including compressors, pumps, etc.) instruments can be removed. It can work and run normally, achieve stable process and ensure safe production. When the fluid enters the filter cartridge with a certain size filter screen, its impurities are blocked, and the clean filtrate is discharged from the filter outlet. When cleaning is required, just take out the detachable filter cartridge and reload it after processing. Yes, it is very convenient to use and maintain.

Technical Parameter

| Material | Medium | Nominal Pressure | Ambient Temperature |

| Aluminum alloy | gasoline diesel kerosene |

0.2㎫ | -45℃ – +55℃ |

Notes on choosing an oil filter

When choosing an oil filter, consider the following suggestions:

◈ The filtration precision should meet the predetermined requirements.

◈ Sufficient flow capacity can be maintained for a long time.

◈ The filter core has sufficient strength and will not be damaged by the action of hydraulic pressure.

◈ The filter core has good corrosion resistance and can work for a long time at the specified temperature.

◈ The filter core is easy to clean or replace.

Therefore, the oil filter should be selected according to the technical requirements of the hydraulic system, according to the filtering accuracy, flow capacity, working pressure, oil viscosity, working temperature and other conditions.