Superior Conductive Fuel Hose

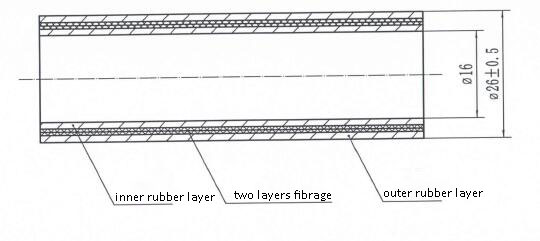

Fuel hose, that is, special oil transfer hose for tankers and oil pumps, is a type of industrial hose. The fuel tank hose is a material composed of inner rubber, outer rubber and middle layer.

Hose is a common tubular rubber product whose main use is in fluid transmission and connection. The hose is characterized by good elasticity and softness, and can adapt to a variety of bending and expansion needs. It is widely used in industry, agriculture, household and other fields. The uses of hoses mainly include the following aspects. First of all, in the industrial field, hoses are often used to transport various liquids, gases and solid particles. For example, in chemical plants, hoses are used to transport various chemical media, such as acids, alkalis, solvents, etc. In the petroleum industry, hoses are used to transport crude oil, natural gas and petroleum products.

Hose is a common tubular rubber product whose main use is in fluid transmission and connection. The hose is characterized by good elasticity and softness, and can adapt to a variety of bending and expansion needs. It is widely used in industry, agriculture, household and other fields. The uses of hoses mainly include the following aspects. First of all, in the industrial field, hoses are often used to transport various liquids, gases and solid particles. For example, in chemical plants, hoses are used to transport various chemical media, such as acids, alkalis, solvents, etc. In the petroleum industry, hoses are used to transport crude oil, natural gas and petroleum products.

Features:

◈High elasticity: The conductive rubber hose has very good elasticity, can withstand large pressure and shear force, and can maintain good elasticity even in complex environments.

◈High tensile strength: The conductive rubber tube has high tensile strength and can withstand large pressure and shear forces without breaking or cracking.

◈Corrosion resistance: Conductive rubber tubes have good corrosion resistance and can be used in various environments, including chemical, electrochemical and physical environments.

◈Insulation: The conductive rubber tube has good insulation properties and can be used in harsh environments without problems such as leakage or short circuit.

Structure:

◈Inner rubber layer: The inner rubber layer is usually made of oil-resistant, corrosion-resistant, and wear-resistant rubber materials, such as nitrile rubber, neoprene, etc. Its main function is to transport oil and ensure the quality and fluidity of the oil.

◈Fabric reinforcement layer: The fabric reinforcement layer refers to a layer of fabric covering the inner rubber layer, usually made of high-strength polyester fiber or aramid fiber. Its main function is to enhance the strength and pressure resistance of the hose, and at the same time it can prevent The hose is burst, twisted or deformed.

◈Outer rubber layer: The outer rubber layer is usually made of rubber materials with stable pressure and wear resistance, such as nitrile rubber, ethylene-propylene rubber, etc. Its main function is to protect the hose from erosion and damage from the external environment, and at the same time it plays a beautifying and protective role.

◈Metal joints: We can also provide various metal joints equipped with fuel hoses for customers to choose. Metal joints are usually made of copper, stainless steel and other materials. They are used to connect hoses to equipment such as oil guns and fuel dispensers. Its main function is to transfer and transport oil products and play a connecting role, while preventing oil leakage, oil leakage and other phenomena occur.

In short, the fuel hose is an important refueling equipment. The quality and performance of its components have a direct impact on the operating safety of the refueling equipment and the quality of the oil. In order to ensure the safety of refueling equipment and the quality of oil products, hoses with reliable quality should be selected and regularly tested and maintained.

Type of Conductive Oil Transfer Hose

According to different conductive forms, our oil transfer hoses are divided into:

◈Type M: metal wire conductive hose

◈Type Ω: rubber conductive hose

According to the temperature level, it is divided into:

◈Normal temperature level: ambient operating temperature is -20℃ to +55℃;

◈Low temperature grade: ambient operating temperature is -40℃ to +55℃.

Under the challenge of how to safely and efficiently transmit hydraulic oil and other media through rubber hoses in the extremely cold external environment, our company organized an analysis of the impact of high-cold areas on mechanical performance, and discussed the problems and failures prone to occur in equipment in low-temperature environments. We discussed solutions and combined with more than 20 years of research & development experience, by adjusting the material ratio and optimizing process technology, we produced a solution suitable for ultra-low temperature transportation of hydraulic oil in engineering machinery and petroleum equipment – -40℃ ultra-low temperature rubber hose. It provides a warm power transmission “lifeline” for engineering machinery and petroleum equipment operating in alpine areas. Our advanced rubber conductive hoses not only solve the problem of cold brittle fracture of hydraulic hoses, rubber seals and metal components under the influence of low temperature factors, but also effectively alleviate the adverse effects on the overall performance and power performance of construction machinery in the cold region.

oil in engineering machinery and petroleum equipment – -40℃ ultra-low temperature rubber hose. It provides a warm power transmission “lifeline” for engineering machinery and petroleum equipment operating in alpine areas. Our advanced rubber conductive hoses not only solve the problem of cold brittle fracture of hydraulic hoses, rubber seals and metal components under the influence of low temperature factors, but also effectively alleviate the adverse effects on the overall performance and power performance of construction machinery in the cold region.

JAYO specializes in supplying standard and durable oil transfer hoses, fittings, couplings and nozzles. Since the founding of the company, we have grown to become experts in the field of gas station equipment. Refueling requires high safety standards, so our mission is to provide only quality and reliable products. Our strong design and engineering departments and production facilities ensure that our conductive hoses are technologically advanced and comply with high safety measures and industry standards.