Calculated Parameters of Bellows for Fuel Dispenser

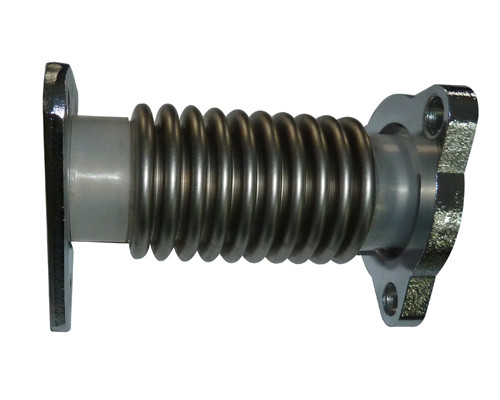

The bellows are designed to connect the hydraulic system of the dispenser to the pipeline. There are a number of advantages over a simple blind connection of the pipeline supplied to the fuel dispenser. A unique construction feature allows bellows expansion joints to dampen differences and fluctuations in the connection of fuel dispensers, tanks and other equipment of gas stations. With this plastic element of the pipeline, it can considerably prolong the lifetime of the fuel pipelines. Bellows expansion joint for fuel dispensers consists of corrugated stainless steel, thus it can be easily deformed and is easy to connect.

The theoretical basis of metal bellows design is plate and shell theory, material mechanics, computational mathematics, etc. The calculated parameters are stiffness, stress, effective area, instability, allowable displacement, pressure resistance and service life.

Compression Resistance

Pressure resistance is an important parameter of corrugated pipe performance. Corrugated pipe at room temperature, the waveform does not plastic deformation can withstand the maximum static pressure, that is, its maximum pressure resistance in general, the bellows is working under a certain pressure (internal or external pressure), so it must withstand this pressure throughout the work process without plastic deformation.

The pressure resistance actually belongs to the category of the strength of the bellows. The key to the calculation is the stress analysis, that is, the analysis of the stress on the wall as long as the maximum stress point on the wall does not exceed the yield strength of the material, the pressure will not reach its pressure resistance.

The pressure resistance actually belongs to the category of the strength of the bellows. The key to the calculation is the stress analysis, that is, the analysis of the stress on the wall as long as the maximum stress point on the wall does not exceed the yield strength of the material, the pressure will not reach its pressure resistance.

The same bellows in other working conditions, the external pressure is better than the stability of the internal pressure, so the maximum pressure resistance by external pressure is higher than that by internal pressure.

When fixed at both ends, the bellows may burst and be damaged at the crest if a large enough pressure is applied to its inner cavity. The pressure value inside the corrugated pipe when starting to burst is called bursting pressure. Burst pressure is a parameter that characterizes the maximum pressure strength. The working pressure is much smaller than the bursting pressure during the whole working process, otherwise the corrugated pipe will break and be damaged.

When the corrugated length is less than or equal to the outer diameter, the calculation result and the actual burst pressure are very close; the actual burst pressure is much lower for slender bellows. The burst pressure is about 3~10 times of the allowable working pressure.

Stability

When both ends are restricted, if the pressure inside the bellows increases to a certain critical value, the corrugated pipe will become unstable.

Allowable displacement

For the corrugated pipe working in compression, its maximum compression displacement is: bellows under pressure, compression to the maximum displacement value that can be produced when the corrugations are in contact with each other, also known as the maximum displacement allowed by the structure, it is equal to the difference between the free length of the bellows and the maximum compression length.

It is equal to the difference between the free length of the bellows and the maximum compression length. The maximum displacement that can be obtained without plastic deformation of the bellows is called the permissible displacement of the bellows.

Corrugated pipe in the actual work process will produce residual deformation, residual deformation, also known as permanent deformation or plastic deformation, corrugated pipe in the force or pressure deformation, when the force or pressure removed, corrugated pipe does not restore the original state of the phenomenon known as residual deformation, residual deformation is usually expressed by the amount of corrugated pipe does not restore the original position, also known as zero offset.

The relationship between corrugated tube displacement and zero offset, whether tensile or compressive displacement, in the beginning of the corrugated tube displacement, its residual deformation are very small, generally less than the corrugated tube standard allowable zero offset value. However, when the tensile (or compression) displacement gradually increased to more than a certain displacement value, will cause a sudden increase in the zero offset value, which indicates that the corrugated tube produces a relatively large residual deformation, after this. If the displacement is increased a little more, the residual deformation will increase significantly. So the bellows generally should not exceed this displacement, otherwise it will seriously reduce its accuracy, stability and reliability and service life.

The allowable compression displacement of the bellows working in compression is larger than the allowable tensile displacement of the bellows working in tension, so the bellows should be designed to work in compression as much as possible. Through the experiment, it is found that in general, the permissible compressive displacement of the bellows of the same material and the same specification is 1.5 times of the permissible tensile displacement.

Allowable displacement is related to the geometric size parameters and material properties of the bellows. In general, the allowable displacement size of corrugated pipe is proportional to the yield strength of the material and the square of the outer diameter, and inversely proportional to the elastic modulus of the material and the wall thickness of the corrugated pipe. At the same time, the relative wave depth and wave thickness also have some influence on it.

Life span

The life of a bellows is the shortest working period or number of cycles that can guarantee normal operation when used under working conditions. Elastic sealing systems made of bellows often work under conditions where they are subjected to variable loads and large displacements for a greater number of cycles, so it is important to determine the service life of bellows. Because the role of bellows is different, the requirements for its service life are also different.

◈When used to compensate the position deviation caused by the installation in the piping system, its life expectancy is only a few times enough.

◈Used in the thermostatic controller with high switching frequency, its life should reach 10,000 times to meet the requirements of use.

◈When used in vacuum switch as vacuum seal, its life time should reach 30,000 times to ensure normal operation.

From the above three use cases, it can be seen that the life time required for the bellows varies greatly due to different use conditions. The using life is related to the fatigue characteristics of the chosen material, and also depends on the size of the residual stress in the formed bellows, the stress concentration and the surface quality. In addition, the service life is related to the working condition.

During the working process of the bellows, its life length mainly depends on the maximum stress generated during the working process. In order to reduce the stress, generally by reducing the working displacement of the bellows and reduce the working pressure to achieve. In general design, the working displacement of bellows should be less than half of its allowable displacement, and its working pressure should be less than half of the pressure resistance of bellows.

The test on the production of corrugated pipe proves that if the corrugated pipe works according to the above specification, its basic life can reach about 50,000 times.

Depending on the nature of the working pressure, the allowable displacement of the bellows is also different. Generally, when the bellows is only subjected to axial load (tension or pressure), its allowable displacement can be selected between 10% and 40% of the effective length of the bellows; and when the bellows is subjected to lateral concentrated force, torsional moment or comprehensive force, the allowable displacement of the bellows should be reduced appropriately.

The application of multi-layer bellows can reduce the stress caused by stiffness and deformation, thus can largely improve the life.

Corrugated pipe in other cases the same but the nature of the working pressure (constant or alternating load) under different conditions, its service life will be different. Obviously, when working under alternating load, its life is shorter than when working under constant load.

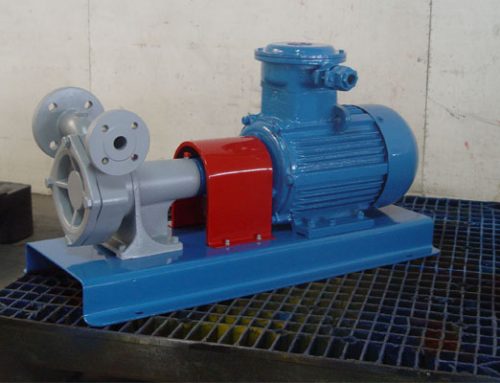

Stainless steel bellows are suitable for all kinds of machines or pipeline connection compensation, such as gasoline dispenser and tanker. With good expansion performance, strong sealing, a variety of non-standard size specifications can be customized, warmly welcome new and old customers to order!