LPG Pump LWB-150 – Ideal Choice for High-Flow Gas Stations

In the LPG refueling equipment industry, balancing flow demand and operational stability had been a challenge until the advent of the LPG pump LWB-150. This high-performance LPG pump, designed specifically for medium to large-sized refueling stations, is redefining the standards for efficient refueling operations with its stable rated flow and groundbreaking durable design.

Many gas stations with a daily refueling capacity of 8-15 tons face a common dilemma: Small LPG pumps cannot meet peak demand, leading to vehicle queues, while large LPG pumps have excess power, resulting in energy waste and accelerated equipment depreciation. The LPG pump LWB-150 precisely addresses this market gap. Its optimized flow curve and intelligent power matching system ensure efficient operation across a high load range, perfectly matching the fluctuating demand of medium-sized gas stations and significantly improving customer satisfaction.

The high-quality LPG pump can automatically adjust the sealing tightness according to the pressure to reduce internal leakage loss. The patented heat dissipation structure ensures stable continuous operating temperature and avoids thermal attenuation. In addition, it can greatly reduce fluid resistance and improve medium delivery efficiency.

The LWB-150 LPG pump is designed for continuous high-intensity use, offering economic efficiency and meeting various LPG refueling needs. Under high pressure differential conditions, it can refuel dual-nozzle LPG dispensers at high flow rates, regardless of whether the LPG tank is above ground or underground.

- Triple Efficiency Design

– **Variable Cross-Section Flow Channel Technology: Reduces fluid resistance by 30%, improving media delivery efficiency;

– **Adaptive Sealing System: Automatically adjusts seal tightness based on pressure, reducing internal leakage losses;

– **Low Temperature Rise Motor: Patented heat dissipation structure ensures stable temperature during continuous operation, preventing thermal degradation;

- Real-World Performance

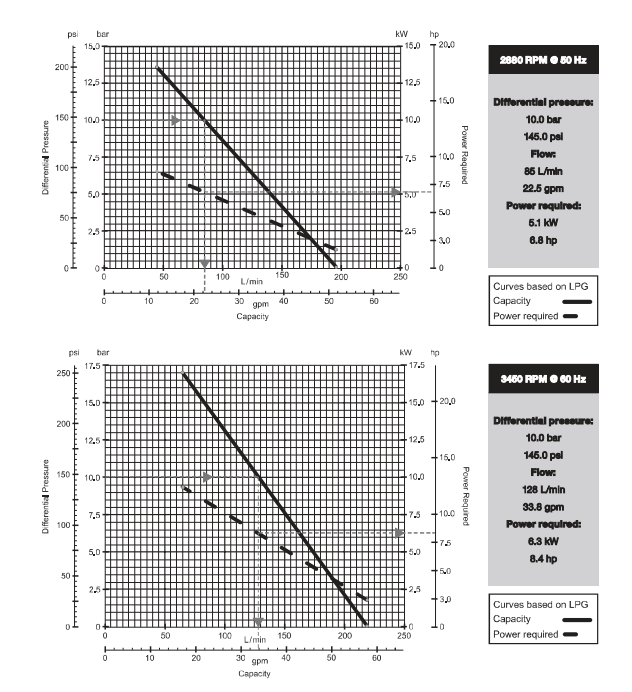

In standard operating condition tests, the LWB-150 demonstrated superior performance indicators. The LWB-150 adopts a modular durability architecture, significantly extending the lifespan of key components.

Applications:

The LWB-150 features a complete active safety architecture. This pump has been certified by the National Product Quality Supervision and Inspection Center and has obtained multiple international safety system certifications. The LWB-150 is particularly suitable for applications such as gas dispensing, filling tanks, LPG vapor recovery, and bulk transportation.

**Urban Medium-Sized Gas Stations: Balancing efficiency and floor space.

**Logistics Fleet Designated Gas Refueling Stations: Handling peak demand for centralized gas refueling.

**LPG Units in Combined Oil and Gas Stations: Requires a stable and reliable medium flow supply.

**Storage Station Transfer Systems: Fast and efficient media transfer.

The LWB-150 features a standardized interface design, ensuring full compatibility with mainstream gas pump control systems. It’s not just an LPG pump; it’s a strategic choice for medium-sized gas stations to enhance their operational competitiveness. With precise flow positioning, groundbreaking efficiency, and superior reliability, it provides gas station operators with an upgrade path from “meeting demand” to “creating an advantage.”

**Choosing the LWB-150 means choosing:**

– Ample refueling capacity to handle peak hours

– Significantly reduced overall operating costs

– Reliable, continuous operation

– Future-oriented investment value

Consult us now for LPG pump LWB-150 technical details and configuration solutions, injecting powerful and efficient core power into your medium-sized gas station!