Notes of Using Self-sealing Refuel Gun

Like chopsticks in a restaurant, the self-sealing refuel gun is the terminal equipment of the fuel dispenser in the gas station, i.e. the part that touches the fuel tank of the car. If the fuel nozzle breaks down without repair in time, or if the staff does not know how to use and operate it correctly, it will affect the refueling efficiency and service quality. And the situation may be serious enough to lead to oil leakage and cause customer dissatisfaction and disputes. Therefore, it is very necessary for gas station staff to understand and operate the fuel nozzle correctly.

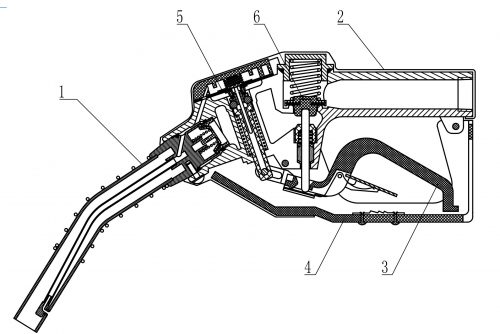

Structure & Function of Self-sealing Oil Gun

The self-sealing oil gun is mainly composed of gun body, oil gun nozzle, main valve, sub valve, switch handle and self-sealing mechanism, etc. Among them, the self-sealing mechanism includes switch membrane, self-sealing bar, self-control bar, steel ball and spring, etc.

◈Oil gun body: it is the major structure of fuel gun, playing a role in fixing and controlling other parts.

◈Oil gun nozzle: The nozzle of the oil gun mainly includes the main body of the nozzle, the intake duct, the intake nozzle, etc. Generally speaking, vehicle oil is divided into 6 points and 4 points nozzle according to diesel and gasoline, diesel fuel uses 6 points nozzle and gasoline uses 4 points nozzle. Its main role is to introduce oil into the vehicle oil injection port, oil diffusion over the air inlet nozzle, so that the self-sealing mechanism role jump gun.

◈The main function of the switch handle, limit plate and stopper is to avoid the fatigue of employees who hold the switch handle for a long time and pay oil. The switch handle is equipped with a stopper, with the help of the limit plate can make the switch handle in three different positions, so that the main valve is placed in the corresponding three openings to get different flow rates.

◈The self-sealing mechanism is the key component that affects the oil gun not to jump the gun not to self-seal, and the structure and function of each part are as follows. The function of the secondary valve is to prevent the outflow of oil in the cavity between the main and secondary valves in the gun body after the main valve is closed, and in the quantitative refueling, when the refueling is finished and the main valve is not yet closed, the secondary valve can prevent the outflow of oil in the gun body and the conductive oil delivery hose. The spring is installed in the upper cavity of the diaphragm of the self-sealing mechanism of the secondary valve, and the main function is to balance the upper pressure of the auxiliary diaphragm, and when the refueling is stopped, the diaphragm is pressed down by the elastic force of the spring to close the secondary valve. The diaphragm is the sealing part of the self-sealing mechanism, dividing the self-sealing mechanism into upper and lower cavities, forming pressure difference, controlling the action of the self-control lever, and realizing the jumping action of the main valve of the oil gun.

Working Principle of Automatic Fuel Nozzle

The self-sealing refuel gun has an independent closed pressure-sensitive working system which is integrated with the gun body. When the main valve of the fuel gun opens and the high-speed oil flow passes through the return valve, the special structural design of the return valve assembly will make the negative pressure inside the pressure-sensitive system. Under the normal working condition, the negative pressure of the pressure-sensing system will be  constantly replenished by the gas through the ventilation tube located in the oil discharge pipe, in order to maintain the pressure above and below the pressure-sensing diaphragm in a balanced state. When the filling level rises and closes the vent pipe (the container is full at this time), the negative pressure in the pressure-sensing system will rise rapidly. At this time, the air pressure on both sides of the pressure-sensitive diaphragm loses the balance (the upper part is negative pressure), and the diaphragm will drive the opening and closing clips to the negative pressure side of the movement to make the gun off the gear, thus completing the self-sealing closing action of the fuel gun within 0.3 seconds. After the oil gun is self-sealed, the self-sealing rod and the self-control membrane are reset under the action of the respective spring force, and the switch is reset with it to restore the oil discharge function.

constantly replenished by the gas through the ventilation tube located in the oil discharge pipe, in order to maintain the pressure above and below the pressure-sensing diaphragm in a balanced state. When the filling level rises and closes the vent pipe (the container is full at this time), the negative pressure in the pressure-sensing system will rise rapidly. At this time, the air pressure on both sides of the pressure-sensitive diaphragm loses the balance (the upper part is negative pressure), and the diaphragm will drive the opening and closing clips to the negative pressure side of the movement to make the gun off the gear, thus completing the self-sealing closing action of the fuel gun within 0.3 seconds. After the oil gun is self-sealed, the self-sealing rod and the self-control membrane are reset under the action of the respective spring force, and the switch is reset with it to restore the oil discharge function.

Notes of Using Self-sealing Refuel Gun

◈Before use, operators should check whether the various parts of the metering fuel gun are in good condition. Adjust the flow rate to the rated flow rate, practice has proved that: the metering fuel gun is used under the rated flow rate, the accuracy is higher.

◈When using it, try to maintain the horizontal position of the fuel gun dial, do not knock and hit. Fuel nozzle should be taken lightly and placed gently, and the combination of the top rod under the main valve and the gun body should be filled with lubricant regularly to ensure flexibility and reliability.

◈Frequently clear out the dirt in the filter and prohibit it from being used to measure water, alkali, acid and other solutions. Keep the oil and gas paths in the self-sealing oil gun smoothly, prevent debris from blocking the oil and gas paths and prevent the self-sealing function from failing.

◈After using the metering fuel gun for a period of time, due to various reasons, the error may appear too large, at this time, you can use the adjustment device to adjust. When adjusting, first screw loose adjusting device, the outer nut, use a small screwdriver to twist the silk plug in. When the table is slow, clockwise twist the silk plug half a week or a number of weeks, repeatedly test several times, until it is considered accurate. Conversely, when the table is fast, counterclockwise twist the silk plug, after the adjustment is completed, the outer nut should be tightened.

◈Daily attention to check whether the oil gun oil leakage, self-sealing mechanism is good.

◈Make good daily cleaning and maintenance.

◈When the metering fuel gun is installed and used, an electrostatic protection device should be installed in the fueling system. Conduct static electricity test once every six months.

Leave A Comment